2014 – 2015

The beginning of a beautiful idea

The idea that something was missing in the current mobility concepts started in 2014. A number of automotive managers found each other in the idea that regular concepts of passenger cars were too big for everyday use, and motorcycles, although exciting, were too dangerous and uncomfortable. The first ideas of an exciting three wheeled concept arose to combine the comfort of a car and the thrill of a motorcycle. This enthusiastic group of automotive managers started brainstorming outside working hours, late into the nights and throughout the weekends.

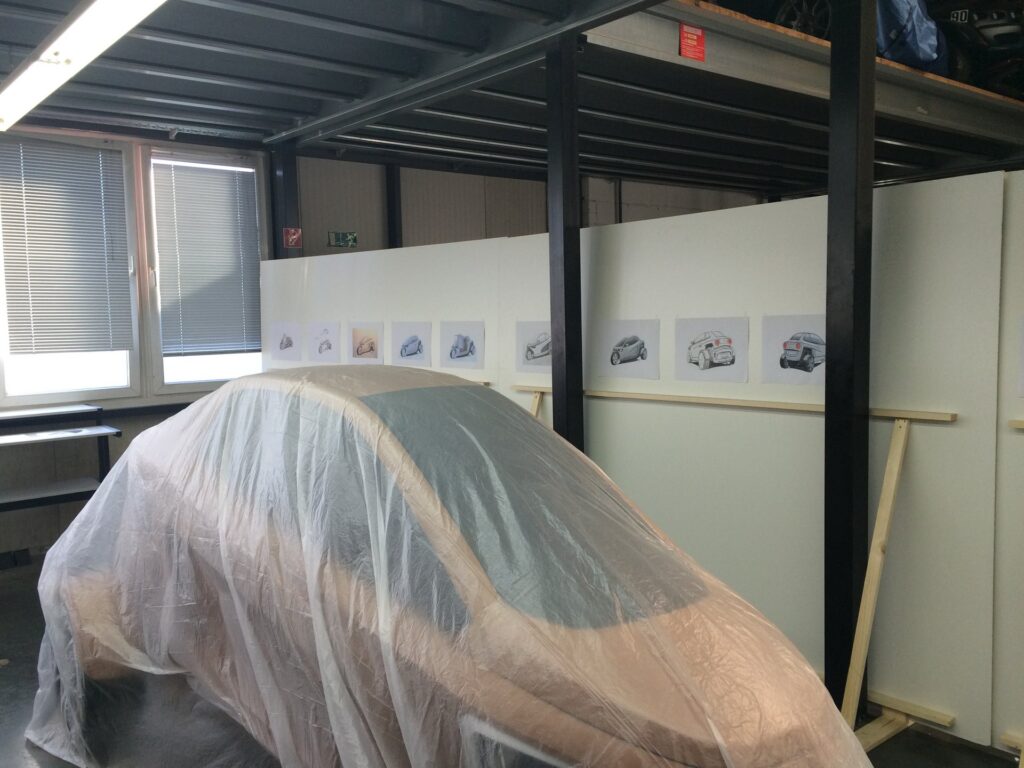

The idea evolved into sketches of what the dashboard should look like, and which regulations were applicable. Gradually, the interior and exterior sketches turned into reality. Suddenly, they were creating 1:5 scale models with various side profiles to compare the impact of various design choices.

Once the design was set up, the participants aligned on market research, customer profiles, timelines and budgets. They decided to make it official and establish Kerv Automotive N.V.

2016 – 2017

The early stages of building and testing

By January 2016, the official Kerv Automotive company was a fact. With a strong connection to the Flemish region to maintain, the decision was made to move the HQ into an old mining location at Houthalen-Helchteren.

By this time the group of enthusiastic managers became the main shareholder, and appointed Arjan Voorbij as the CEO and project leader. His mission was to gather a team of engineers to design and develop the vehicle and the active electrohydraulic tilting system at its heart. A unique challenge to ensure a unique driving experience.

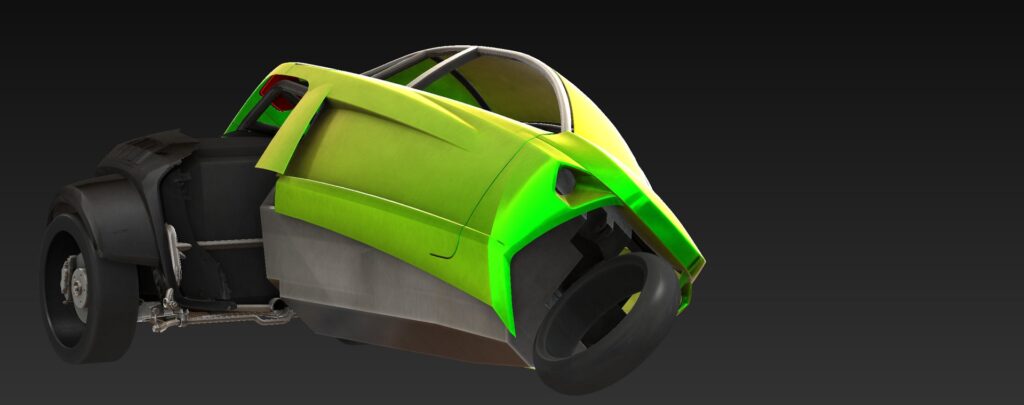

The DNA of the vehicle was finalized into a 1:1 clay model, and the process continued with some wooden interior models. A complete, green static model was built to check and merge the combined interior and exterior design. This model was the basis for the engineering process and the first regulations checks.

A dedicated team of engineers was gathered to perform most tasks with regard to design and engineering in-house. They translated conceptual design into a feasible prototype. An old abandoned building, next to the main offices, was first used for the prototyping. It turned out, this makeshift ‘workshop’ was previously used by the Red-Cross as a training office and by the local youth population for their graffiti … ‘courses’. Nevertheless, it was found to serve well for construction of the first functional prototypes.

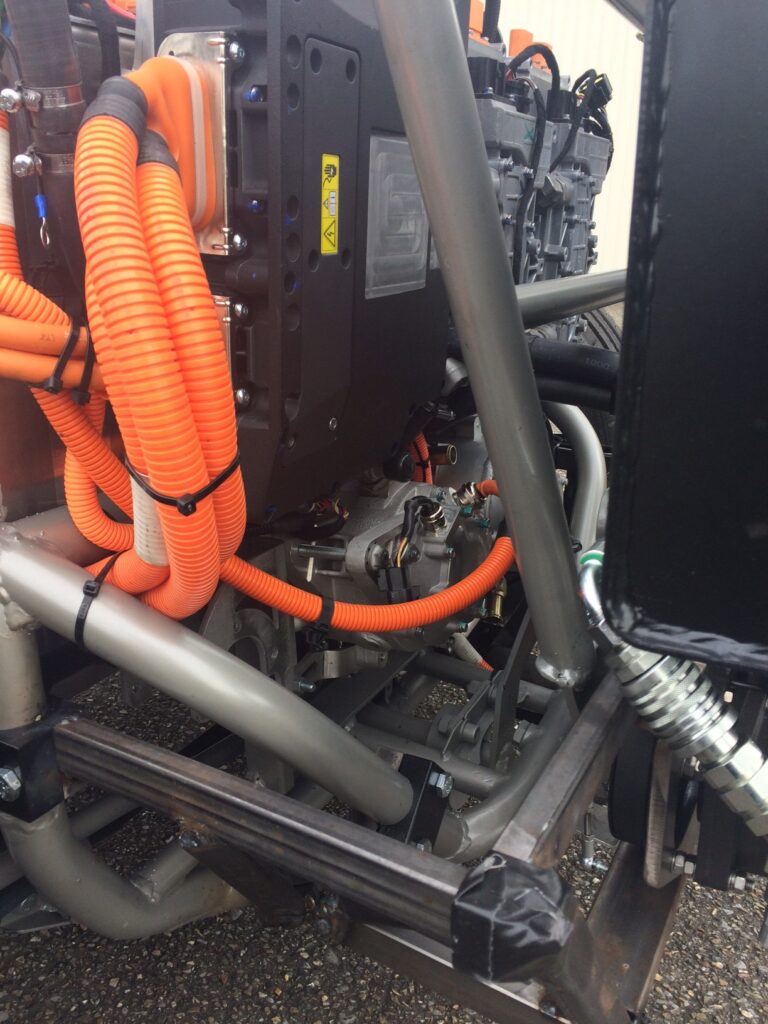

With the resources from additional shareholders, the first prototypes were built using a tubular frame without interior and exterior. Because of their unusual look, they were internally called Mad Max Kerv prototypes, and abbreviated to MMK1, MMK2, etc. Their main purpose was R&D of the proposed in-house developed tilting system and corresponding vehicle dynamics aspects.

The powertrain was provided by Punch Powertrain, a global automotive supplier located in Sint-Truiden in Belgium. Lots of test days were spent at the landing strips of the former military airbase of Brustem nearby.

2018 – 2019

New input for a complete package

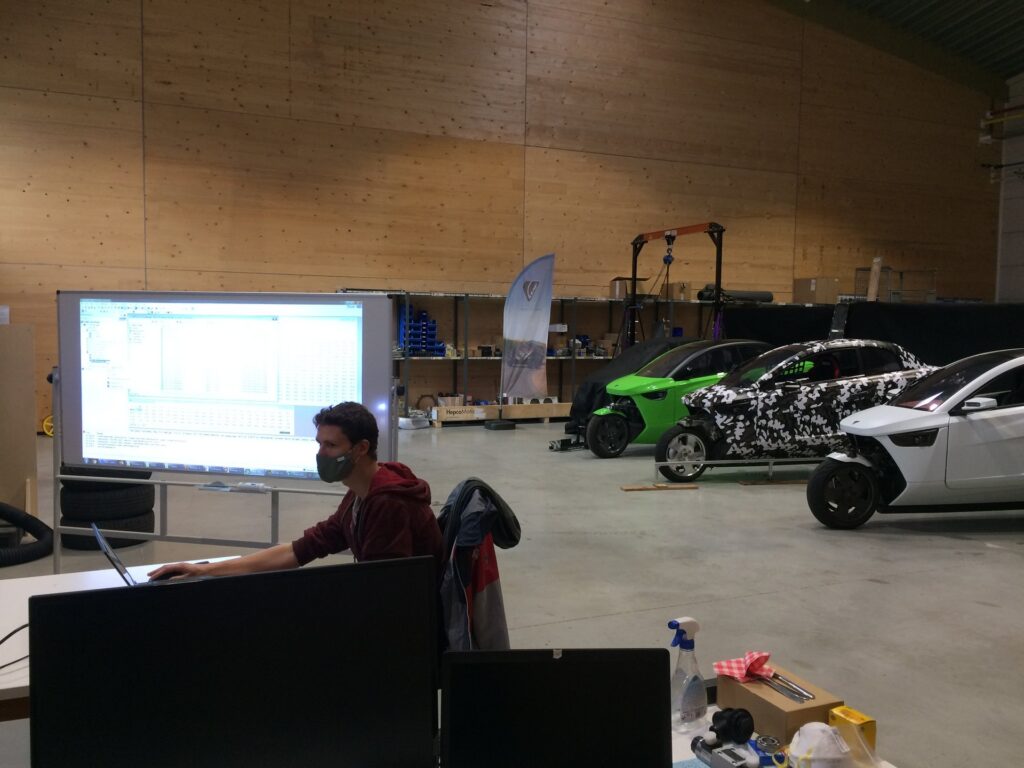

Step by step, we gathered the unique key knowledge to develop the active tilting system. The need for -financial- resources was met by means of a buy-in of a new global shareholder in 2018. They funded the move to 2 new workshops for prototyping and further development of supporting systems and body electronics.

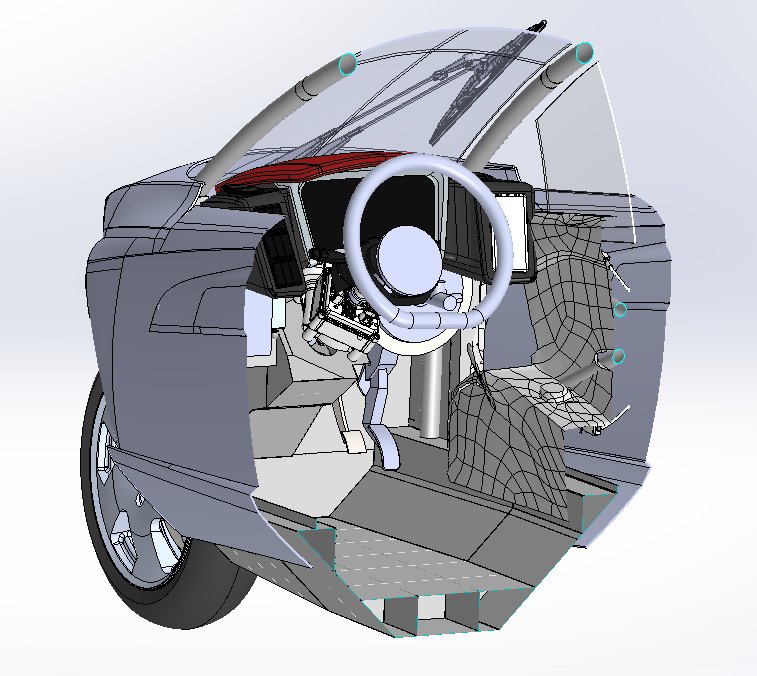

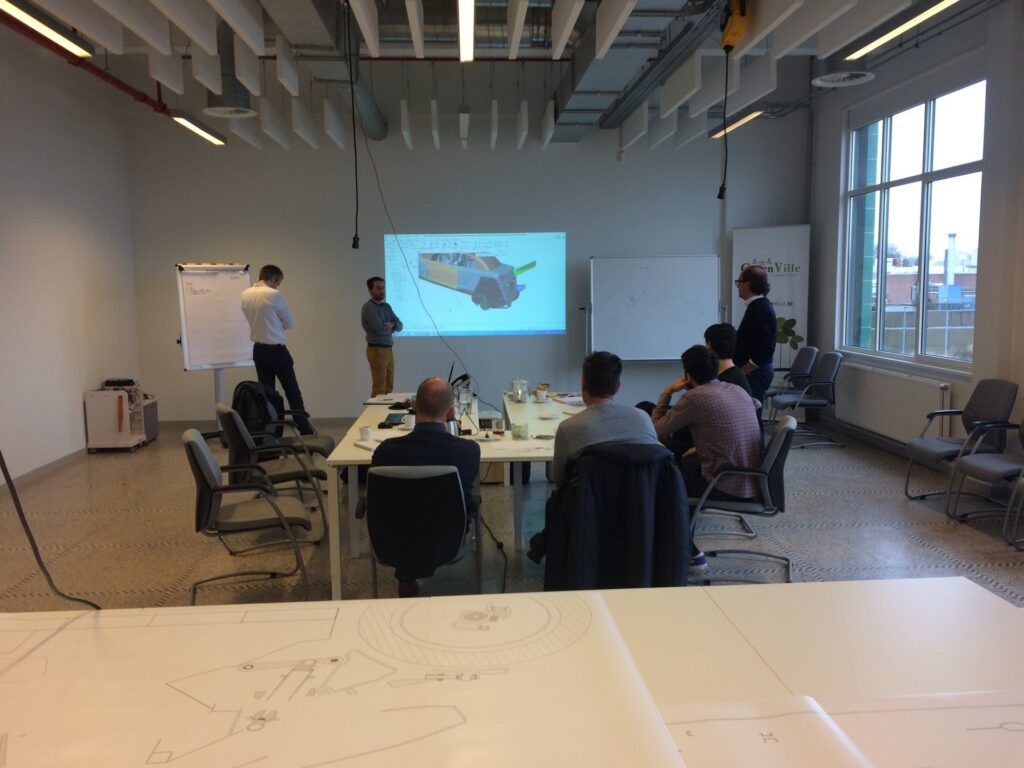

Meanwhile in the office buildings, parallel to the Mad Max vehicle test sessions, engineers were completing the vehicle design, adding parts into a complete 3D CAD (Computer Aided Design) model, serving as the basis for type-approval regulations within the EU. They would be the first to merge the functional design of the tubular frame prototypes, with the previously approved exterior glass-fiber panels, and would be later called B-sample prototypes.

At the test track, speeds were increased and at some point, the Brustem airbase was found too small for extensive testing. The prototype had been tested extensively for optimization, up to and exceeding the limits of grip at Brustem.

As safety is of utmost importance to us, we started development a full computer MBS (Multi-body simulation) model to predict and finetune vehicle behavior where necessary. These were common practice by other vehicle manufacturers for two- and four-wheeled vehicles, but a setup like this had never been done before for a tilting three-wheeler. Challenge accepted!

We were at a stage where the first B-sample prototype, built in parallel in one of the new workshops, was near completion. This meant we could leave the Mad Max style period and continue testing on a higher level and include other aspects in testing. By this time, we were also at the stage where we filed some critical knowledge into patents related to the unique technical aspects and vehicle design. Several patents were granted globally in 2019.

In November 2019, the first B-sample was fully completed and ready to continue testing in a more realistic vehicle setting. Development was speeding up and we managed to start first validation tests of the multi-body simulation model.

2020 – 2021

Kerv hits the road

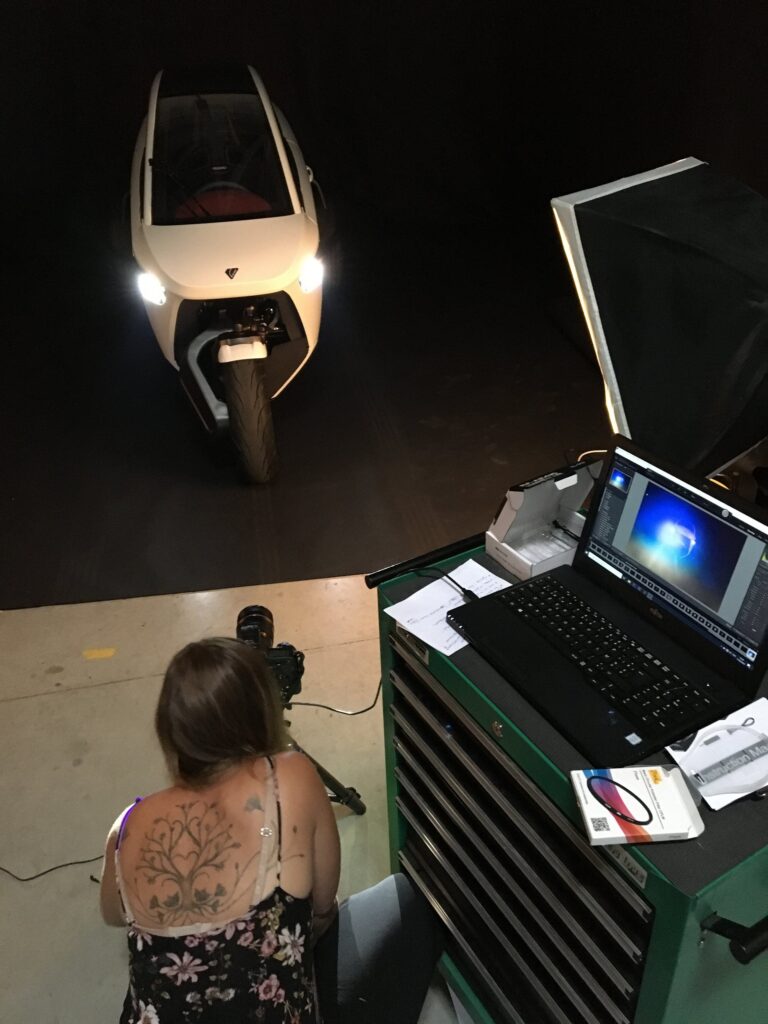

During 2020 and 2021, while refining the tilt controls with the first B-sample (BS-1) tests, we completed the second B-sample (BS-2). This would evolve our prototypes from functional and performance testing into a more demonstration-worthy vehicle, with a full interior and an attractive satin-white / dark grey paint job. In 2021, we completed construction of the 3rd B-sample chassis for EV-development.

Based on field results and enthusiastic reactions, some events were organized to share the unique driving sensation with potential technology partners for further evolving the prototypes into production models.

Early 2020, the next funding round was started to prepare for production and sales. Unfortunately, the Covid-19 pandemic hit hard, slowing down the economy and severely hindering our funding round. By the time the economy could recover, and most of the financial buffer depleted, the combustion engine did not match investors’ expectations.

With a heavy heart, we were forced to put the Kerv project on hold at the end of 2021.

2022 – 2023